Alright friends, gather around because today we are talking about the GLP-1 drug environmental impact. Yes, those superstar medications like Ozempic and Wegovy that everyone is buzzing about for diabetes and weight loss.

These medicines are changing lives and helping millions of people manage metabolic disease. But here comes the plot twist. Behind the medical success story sits an environmental challenge that most people never hear about.

GLP-1 medications are made using advanced peptide chemistry. That science is incredible. However, the traditional way these drugs are manufactured creates a massive amount of chemical waste. Researchers across the world are now asking a big question. Can we keep the medical benefits while reducing the environmental footprint?

Let’s unpack the science, the scale of the waste, and the new water-based breakthrough that could transform how these life changing medicines are made.

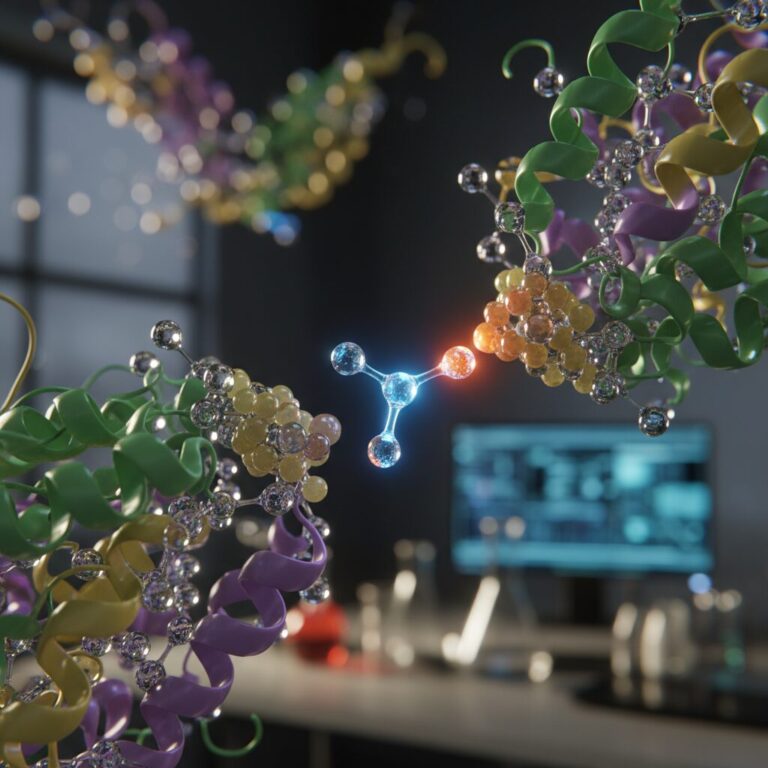

GLP-1 drugs belong to a broader family called peptide therapeutics. Peptides are short chains of amino acids that act like tiny biological messengers. They help regulate appetite, blood sugar, hormones, and many essential processes in the body.

Today there are more than 80 peptide-based medicines approved worldwide. They treat cancer, diabetes, autoimmune disorders, and rare diseases. This number continues to grow rapidly as biotech companies invest heavily in peptide research.

Because of this growth, manufacturing demand has exploded. And that is exactly where the GLP-1 drug environmental impact begins to show.

If you want a simple way to picture peptide manufacturing, think of building a giant LEGO tower one brick at a time. Each amino acid is added step by step in a precise sequence. That process is called solid phase peptide synthesis.

Now we reach the messy part of the story.

Traditional peptide manufacturing relies heavily on organic solvents. These chemicals are widely used in industrial production. One common example is dimethylformamide, often called DMF. These solvents help clean and prepare the growing peptide chain during each step of synthesis.

Here is the issue. Every single step requires washing away leftover chemicals before the next amino acid can be added. When this process is repeated at industrial scale, the waste becomes enormous.

Researchers from the University of Melbourne estimate that manufacturing semaglutide, the active ingredient in Ozempic and Wegovy, could generate around 123 million pounds of solvent waste every year. This is only one drug. Dozens of peptide drugs are produced globally.

Disposal is expensive, energy intensive, and environmentally challenging. As demand for GLP-1 drugs continues to surge, the scale of this challenge keeps growing.

This is why the GLP-1 drug environmental impact has become a serious topic in pharmaceutical sustainability discussions.

GLP-1 medications are experiencing historic demand. Prescriptions are increasing worldwide as obesity and diabetes rates continue to rise. In addition, generic versions are expected in the coming years, which will likely increase production even more.

More demand means more peptide manufacturing. More manufacturing means more solvent use. And more solvent use means more waste.

So the real challenge is not whether GLP-1 drugs are valuable. They absolutely are. The challenge is how to produce them responsibly at scale.

That brings us to the exciting part of the story.

Scientists began asking a bold question. What if peptide drugs could be manufactured using water instead of harsh organic solvents?

At first this idea sounded almost impossible. Amino acids usually do not dissolve well in water at high concentrations. They also tend to react poorly when scientists try to link them together in aqueous conditions.

However, recent research has shown promising results. Scientists discovered that pairing amino acids with specific salts allows them to dissolve effectively in water. This creates a cleaner reaction environment and reduces the need for toxic solvents.

Researchers are now exploring peptide synthesis performed primarily in water. This approach could dramatically reduce chemical waste and lower the environmental footprint of drug manufacturing.

It is important to note that this method is still in the research and scale up phase. It has not yet replaced commercial manufacturing. However, the early results are extremely promising.

This innovation could transform the GLP-1 drug environmental impact in the coming years.

If this technology scales successfully, the benefits could be enormous.

First, solvent waste could drop dramatically. That means less environmental burden and lower disposal costs.

Second, manufacturing could become more sustainable and energy efficient. Water is safer, cheaper, and easier to handle than organic solvents.

Third, pharmaceutical companies could reduce regulatory and waste management challenges while continuing to meet global demand.

This is a rare moment where environmental sustainability and medical innovation align perfectly.

The story of GLP-1 drugs is far from over. These medicines are reshaping how we treat metabolic disease. At the same time, researchers are reshaping how we manufacture them.

The pharmaceutical industry has a long history of innovation. From green chemistry to sustainable manufacturing, the momentum is clearly shifting toward environmentally responsible production.

The GLP-1 drug environmental impact may soon look very different from what it does today.

And that is good news for patients, researchers, and the planet.

GLP-1 medications are powerful tools in modern medicine. They improve health outcomes, support weight management, and help millions of people live healthier lives.

Yet every innovation brings new responsibilities. Understanding the GLP-1 drug environmental impact helps ensure that medical progress does not come at the expense of environmental sustainability.

The move toward water based peptide synthesis shows what is possible when scientists rethink the status quo. The future of pharmaceutical manufacturing may be cleaner, greener, and smarter than ever before.

If you are fascinated by peptide science and sustainable innovation, this space is just getting started.

All human research MUST be overseen by a medical professional.